ENGINEERING

In TEYDESA CONECTORES S.A.U. we have an advanced Engineering Department with the required machinery and computerized controlled tooling for the testing of existing and the development of innovative products at customer’s requests.

This engineering area has the mission to become the best ally for the industry 4.0. The industrial environment needs customized and exclusive, automated equipment with the need to guarantee the quality of its products.

Our Engineering department is the base in the development of projects. To meet our objectives we have qualified human talent, engineers with design, manufacturing and maintenance experience supported by the latest design and simulation programs.

QUALITY

The quality control department works in accordance with the ISO 9001 standard.

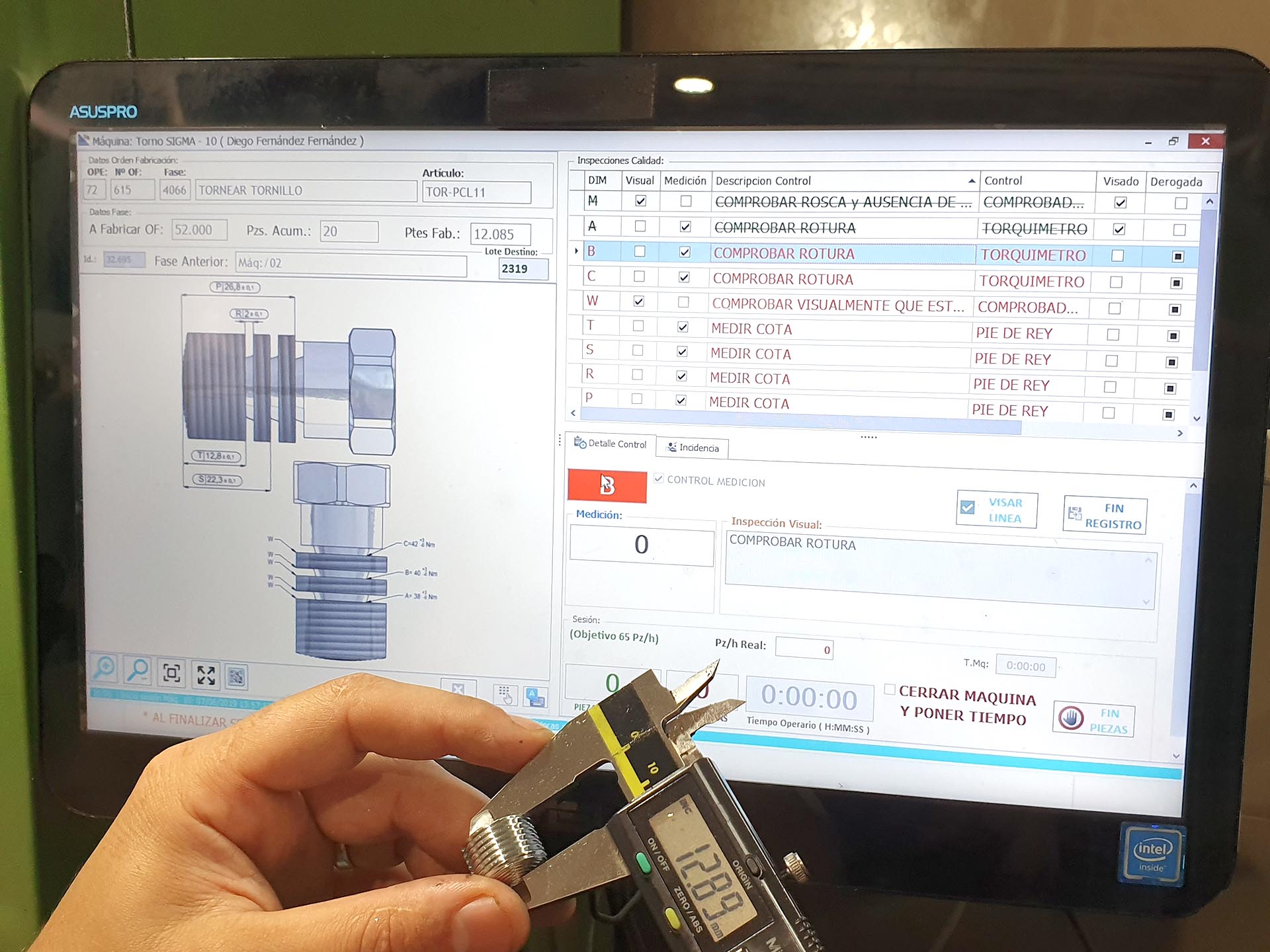

The quality in the production process works in principal with a self-control system verified by Engineering and the operator assigned to each CNC machine in use for accurate measurements, dimensions and visual control in the designated manufacturing process and time for verifiable quality records, This includes the Lot Number stamping of each connector which verifies the week and year of manufacturing.

When quality records are produced the operator finds the pattern with the appropriate dimensions indicating which measuring device he or she should use for quality control.

The measurement goes directly from the measuring device to a computer via WIFI. In the event that the measurement is not correct, the Engineer is notified of the error and corrects the problem.

This process ensures that the end product is always correct.

During different work shifts the quality control group performs random checks of the manufacturing process and finally performs the last quality control checks before products go into final stock.

Home – Company – Product – Privacy Policy / Legal Warning – Contact

TEYDESA CONECTORES S.A.U. – Email: info@teydesa.es – Telf: +34 988 221 450